Product Details -

A conveyor belt is a mechanical system used to transport materials or goods from one point to another, typically within a manufacturing or distribution facility. It consists of a continuous loop of material, usually made of rubber, fabric, or metal, which is driven by rollers or pulleys. Conveyor belts are commonly used in industries such as mining, agriculture, automotive, food processing, and logistics to automate the movement of materials and improve efficiency in production processes. They come in various types and configurations to suit different applications, including flat belts, roller conveyors, belt conveyors, and overhead conveyors.

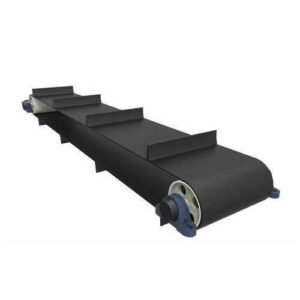

Conveyor Belt

Features

Conveyor belts are essential components in various industries for transporting materials or products from one point to another efficiently. Here are some common features of conveyor belts:

Belt Material: Conveyor belts are typically made from various materials such as rubber, fabric, plastic, leather, metal, or a combination of these materials. The choice of material depends on factors such as the type of product being transported, environmental conditions, and operational requirements.

Belt Structure: Conveyor belts consist of multiple layers, including the carcass or base material, cover, and optionally additional layers for reinforcement or protection. The carcass provides strength and support, while the cover protects the carcass and the conveyed material from wear, abrasion, and environmental factors.

Belt Width and Length: Conveyor belts come in various widths and lengths to accommodate different applications and space constraints. The width and length of the belt are selected based on factors such as the volume of material to be transported, the size of the conveyor system, and the layout of the facility.

Drive System: Conveyor belts are driven by various mechanisms, including electric motors, hydraulic systems, or pneumatic systems. The drive system provides the necessary power to move the belt and transport materials along the conveyor line.

Rollers and Idlers: Conveyor belts are supported by rollers or idlers along their length to reduce friction and facilitate smooth movement. These rollers or idlers are typically made from steel or other durable materials and are strategically placed to support the belt and guide it along the conveyor path.

Tensioning System: Conveyor belts require proper tensioning to ensure smooth operation and prevent slippage or sagging. Tensioning systems may include adjustable pulleys, tensioning devices, or mechanical tensioners to maintain the desired tension in the belt.

Safety Features: Conveyor belts are equipped with various safety features to protect workers and prevent accidents. These features may include emergency stop switches, safety guards, conveyor belt alignment systems, and safety sensors to detect obstructions or abnormalities.

Customization Options: Conveyor belts can be customized to meet specific application requirements, including specialized coatings for handling food or chemicals, cleats or flights for inclined or vertical conveying, and special configurations for curved or spiral conveyors.

Maintenance and Cleaning: Proper maintenance and cleaning are essential for ensuring the longevity and efficiency of conveyor belts. Conveyor systems may include features such as belt scrapers, belt cleaners, and automated cleaning systems to remove debris, spills, and buildup from the belt surface.

Integration with Automation Systems: Conveyor belts are often integrated with other automated systems, such as robotic arms, sorting machines, and packaging equipment, to create fully automated production or distribution lines. Integration features may include sensors, actuators, and control systems to c