Product Details -

A conveyor roller is a cylindrical component used in conveyor systems to facilitate the movement of materials or products along a predetermined path. These rollers are typically made of metal or plastic and are mounted onto frames or shafts to support and guide the conveyor belt. Conveyor rollers come in various sizes and configurations to suit different applications, such as gravity rollers for simple material handling or powered rollers for automated systems. They play a crucial role in ensuring smooth and efficient transportation of goods in industries such as manufacturing, distribution, and logistics.

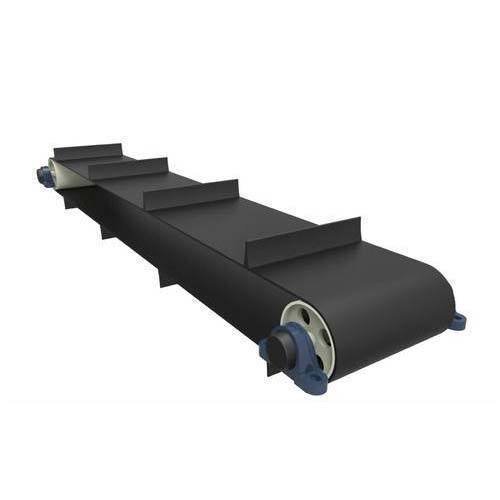

Conveyor Roller

Features

Conveyor rollers are crucial components in material handling systems, providing efficient movement of goods in various industries. Here are some key features of conveyor rollers:

Roller Material: Conveyor rollers are typically made from materials such as steel, stainless steel, plastic, or rubber, depending on the application requirements.

Roller Diameter: The diameter of the roller affects its load-bearing capacity and performance. Larger diameter rollers are often used for heavier loads, while smaller ones are suitable for lighter items.

Bearing Type: Bearings are essential for smooth rotation of the roller. Common types include ball bearings, roller bearings, and precision bearings, each offering different levels of durability and smooth operation.

Shaft Configuration: The shaft of the roller can be solid or hollow, with options for different mounting configurations such as spring-loaded shafts or threaded shafts.

Axle Retention: Rollers may feature various mechanisms to retain the axle, such as snap rings, circlips, or retaining washers, ensuring the stability and integrity of the roller assembly.

Roller Surface: Depending on the application, rollers may have different surface finishes such as grooved, knurled, or coated surfaces to provide better grip or reduce friction.

Roller Length: The length of the roller determines its contact area with the conveyed material and influences the overall stability and efficiency of the conveyor system.

Load Capacity: Rollers are designed to support specific load capacities, which should be considered when selecting rollers for a particular application to prevent overloading and premature failure.

Noise Reduction: Some rollers are designed with features to minimize noise during operation, such as precision bearings, noise-reducing coatings, or vibration-dampening materials.

Corrosion Resistance: For applications in corrosive environments, rollers may be coated or constructed from materials resistant to rust and chemical damage, ensuring longevity and reliability.

Temperature Resistance: In extreme temperature conditions, rollers should be capable of withstanding high or low temperatures without compromising performance or structural integrity.

Customization Options: Manufacturers often offer customization options for conveyor rollers, allowing for specific modifications to meet unique application requirements, such as special coatings, sizes, or configurations.